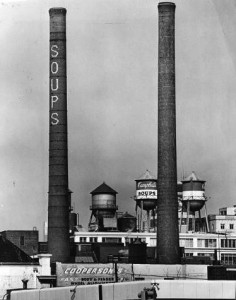

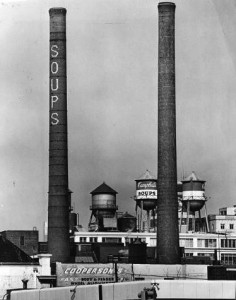

Campbell Soup Company

Anderson & Campbell Preserve Company formed in Camden, New Jersey in 1869. Throughout the nineteenth and twentieth centuries the company grew to become one of the largest food companies of the twenty-first ...

Daniel Sidorick has taught history at Temple and Rutgers Universities and the College of New Jersey. His book Condensed Capitalism: Campbell Soup and the Pursuit of Cheap Production in the Twentieth Century (Cornell University Press) was awarded the Richard P. McCormick Prize by the New Jersey Historical Commission.

Anderson & Campbell Preserve Company formed in Camden, New Jersey in 1869. Throughout the nineteenth and twentieth centuries the company grew to become one of the largest food companies of the twenty-first ...

For most of Philadelphia's history, food processing was an important industry, pioneering new products and employing tens of thousands of workers. Many well known national corporations got their start as small businesses in Philadelphia. Shifts in corporate strategies led to a decline in the industry in the region by the twenty-first century, though many small food processors ...

The "Scientific Management" movement was born in early twentieth-century Philadelphia factories but spread rapidly, transforming not only management techniques but also popular conceptions of industrialized society itself. According to its founders, the system simply sought the "one best way" to perform any task. But its time-study engineers, along with the assembly line, came to symbolize ...

Connecting the Past with the Present, Building Community, Creating a Legacy