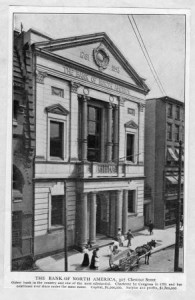

Bank of North America

Chartered May 26, 1781, by the Continental Congress under the Articles of Confederation, this enterprise was the first national and truly commercial bank in the United States. Officially titled The President, Directors, and Company of the Bank of North America (BNA) until 1825, the bank was the first created by the national government to do business with and for the government. Though ...