Gunpowder Industry

By Kim Burdick

Essay

The Mid-Atlantic gunpowder industry flourished in the nineteenth century along the Brandywine River in Delaware and spread into Pennsylvania, New Jersey, and other states. Long synonymous with the name duPont, the industry began in 1802 when Eleuthère Irénée duPont (1771–1834), a French refugee and former student of famous chemist Antoine Lavoisier (1743–94), began manufacturing gunpowder along the banks of the Brandywine.

Using charcoal made from local willow trees, sulfur, saltpeter shipped in on the Delaware River, and water power controlled by French water wheels and turbines, duPont’s mill increased production rapidly, making and selling 39,000 pounds of gun powder in 1804 and triple that amount the next year. During the War of 1812, sales jumped when the United States government bought powder from DuPont. With the proceeds, the company acquired additional land for industrial use at a site on the Brandywine known as Hagley, a name of English origins bestowed by a former owner. With the expansion into the Hagley Yards, E.I. du Pont de Nemours and Company was on its way to becoming one of the world’s largest producers of explosives.

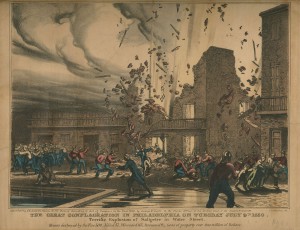

Making gunpowder was perilous work for the duPonts and their workers, who lived in communities near the mill. In the most dangerous part of the process, ingredients were mixed wet, then ground down to a paste called “serpentine,” which was pushed through a mesh to form granules. These granules were allowed to dry, pressed into blocks, and passed through a mill twice to produce a fine powder. Safety rules were strict. To guard against igniting the powder, machinists’ whale oil lamps were encased in glass, powdermen’s boots were held together with wooden pegs, and the cart-horses’ hooves were encased in leather. On New Year’s Day 1811, the mill posted a notice stating, “All kind of play or disorderly fun is prohibited.”

Despite precautions, in June 1815, the pounding mill exploded, and eight workmen died. In 1818, a more massive explosion, attributed to a foreman’s drinking, destroyed five mill buildings, killed thirty-six workers and injured E.I.’s wife, Sophie (1775–1828). Alcohol was then banned from the work site and E.I. and Sophie’s son, Alfred Victor duPont (1798-1856), worked closely with powdermen to rebuild the mill. He became head of the company in 1837, succeeded after his retirement in 1850 by his brother, Henry duPont (1812-89). Their younger brother, Alexis I. (1816-57), died along with five others while trying to extinguish another fire at the mill in 1857.

Popular With Sportsmen

Demand for gunpowder continued after the War of 1812 as DuPont gunpowder became popular with sportsmen, and an energetic period of national development between 1830 and 1860 increased the need for gunpowder to blast open coal mines and build roads, canals, and railroads. The duPonts responded with innovation and expansion. In 1857, Lammot duPont (1831-84)–the son of Alfred Victor duPont— developed “B” blasting powder with a more powerful blast than traditional black powder by substituting sodium nitrate for potassium nitrate. In 1859, the company purchased the Wapwallopen powder factory outside Wilkes-Barre, Pennsylvania, for its manufacture. Further black powder research yielded “Mammoth Powder” for use with heavy artillery.

During the Civil War, the Brandywine powder mill produced nearly one-third of the Union’s requirements. As a result of accelerated wartime production, the packing room exploded on February 26, 1863, destroying 10,000 pounds of powder and killing thirteen men. Two more explosions occurred that year, killing forty more.

Continuing to expand after the Civil War, by 1902 DuPont operated forty gunpowder and explosives plants, from the Mid-Atlantic to the new western states, leading to antitrust claims. In 1906, Robert S. Waddell, a former employee and owner of his own powder company, claimed the “DuPont Powder Trust” was bilking the U.S. government through a monopoly on the manufacture of military gunpowder. As a result, the Sherman Antitrust Act forced the 1913 creation of Hercules Powder Company and Atlas Powder Company, each having the capacity to produce 50 percent of the country’s black powder and 42 percent of its dynamite. Atlas began business on Jan. 1, 1913, with four former DuPont black powder plants at Ooltewah, Tennessee; Belleville, Illinois; Pittsburg, Kansas; and Patterson, Oklahoma, and three ex-DuPont dynamite plants at Landing, New Jersey; Hancock, Michigan; and Webb City, Missouri. Although DuPont had been forced to split, Hercules and Atlas were staffed primarily by former DuPont executives, and the connection between them and the parent company remained largely intact and both firms evolved into strong, independent chemical companies. The court decision clearly signaled to DuPont that the explosives business could no longer be its major growth vehicle. Thus, government trustbusters played a major role in DuPont’s evolution away from explosives and into a broader base of chemical products.

During World War I, the government once again called upon DuPont to produce explosives. In Deepwater, New Jersey, an unincorporated area of Salem County, the company expanded its Carney’s Point plant (built in 1892) to nearly seventy times its prewar capacity. Five additional plants also helped to meet the need. The largest, in Old Hickory, Tennessee, produced raw materials for smokeless powder: sulfuric acid, nitric acid, and guncotton (a nitrate product).

Long after the war, in 1934, the extent of the DuPont Company’s wartime production led to accusations of war profiteering. The duPonts denied the charges when they and other munitions manufactures testified before the Senate Munitions Investigating Committee.

Entrepreneurial Research

After the war, the DuPont Company actively diversified as an entrepreneurial research firm, continuing a strategy of modernization begun in 1902 after purchase of the firm by cousins Pierre duPont (1870-1954), T. Coleman duPont (1863-1930), and Alfred I. duPont (1864-1935). Aided by company executive Arthur Moxham (1854-1931), the firm’s new generation of owners sought new outlets for products, independent sources of raw materials, and expansion into fields beyond explosives. (By the end of World War I the peacetime use of artificial fibers proved to be more profitable than explosives.) Moxham instructed his staff to think of DuPont as a chemical manufacturer.

Although it remained a producer of explosives, the company closed the Hagley Yard in 1921, and by 1930 its products included upholstery fabrics, gasoline additives, plastics, Duco lacquers, rayon, cellophane, and plastics. For World War II, DuPont designed, constructed, and operated a plutonium plant for the Manhattan Project, which produced the first atomic bomb, but by 1975 the company stopped producing gunpowder. Its product offerings by the early twenty-first century included communications technologies, performance materials, coatings and color technologies, safety and protection, and agriculture and nutrition. While DuPont grew as a Delaware-based research and manufacturing company employing more than 60,000 people worldwide, its original powder works on the Brandywine became the site of the Hagley Museum, where visitors could learn about the industrial past.

Kim Burdick earned her M.A. in American Folk Culture & Museum Studies from Cooperstown Graduate Programs at SUNY Oneonta. She later served as a joint Hagley-Winterthur Research Fellow. She also holds an M.P.A. from the College of Urban Affairs at the University of Delaware. She is an award-winning public historian who has coordinated a number of major projects, including the nine-state Washington-Rochambeau Revolutionary Route. She is currently the curator of the historic Hale Byrnes House. (Author information current at time of publication.)

Copyright 2015, Rutgers University