Paints and Varnishes

Essay

From colonial times to the nationwide deindustrialization trend starting in the 1950s, Philadelphia played a leading role in providing American and overseas markets with quality paints and varnishes. “Oil and Colours” merchants of the colonial period turned, during the early nineteenth century, into family-owned-and-managed manufacturing companies, as they opened paint and varnish factories in Center City and later in the industrial suburbs of Kensington, Camden, and South Philadelphia. Companies including Harrison Brothers, Wetherill & Brothers, and Christian Schrack and Co. supplied artists, carriage and coach makers, furniture makers, ship builders, house painters, and later automobile companies with paints, pigments, oils and varnishes, and established Philadelphia’s reputation as a premier manufacturing center of fine paints and varnishes.

Even before rising to industrial supremacy in the early nineteenth century, Philadelphia imported, prepared, consumed, and exported coating materials in a comparatively large scale. Shipyards and carriage-making workshops often included a paint shop where professional painters ground and mixed pigments with boiled oils and resins to prepare a coating intended for a specific use. Painters or merchants engaged in the commerce of drugs, glass, oils, and “colours” (pigments) imported most of their raw materials for paint preparations from Europe, particularly England. Philadelphia was the point of entry to the New World for expensive pigments, including chrome yellow, vermilion (red mercuric sulfide), verdigris (green copper acetate), and Prussian blue (ferrocyanide acid). Some prominent merchants, such as the Elliott family established on Front Street by the mid-eighteenth century, also were apothecaries and compounded small quantities of bright pigments. Linseed oil, the most widespread binder for paints and drying oil for varnishes, came entirely from transatlantic imports until domestic production started in the late eighteenth century. Later, mills erected on the Pennypack Creek watershed in 1842 supplied Philadelphia with large quantities of linseed oil, extracted from flaxseed.

Dependence on foreign imports was particularly acute for lead-based pigments, which were pervasive prior to a federal ban on lead paint in 1978. White lead (a complex of lead carbonate and lead hydroxide), red lead, and litharge (lead oxides) were key ingredients in nearly all paints and varnishes. White lead served extensively as a base for mixing other pigments to create a variety of tints. Red lead and litharge were systematically introduced into varnish preparations as driers. Thus, when prominent pigment merchants or apothecaries of Philadelphia turned to large-scale manufacturing at the turn of the nineteenth century, they first concentrated on lead-based pigments; establishing a domestic paint and varnish industry depended on their success in competing with English manufacturers.

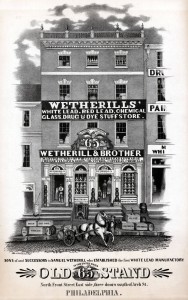

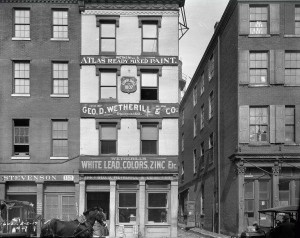

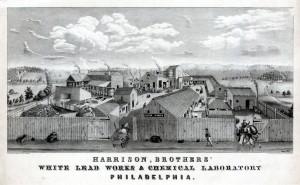

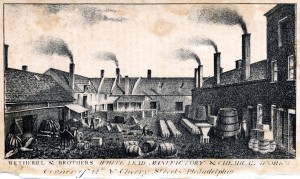

Paint-Materials Business Booms

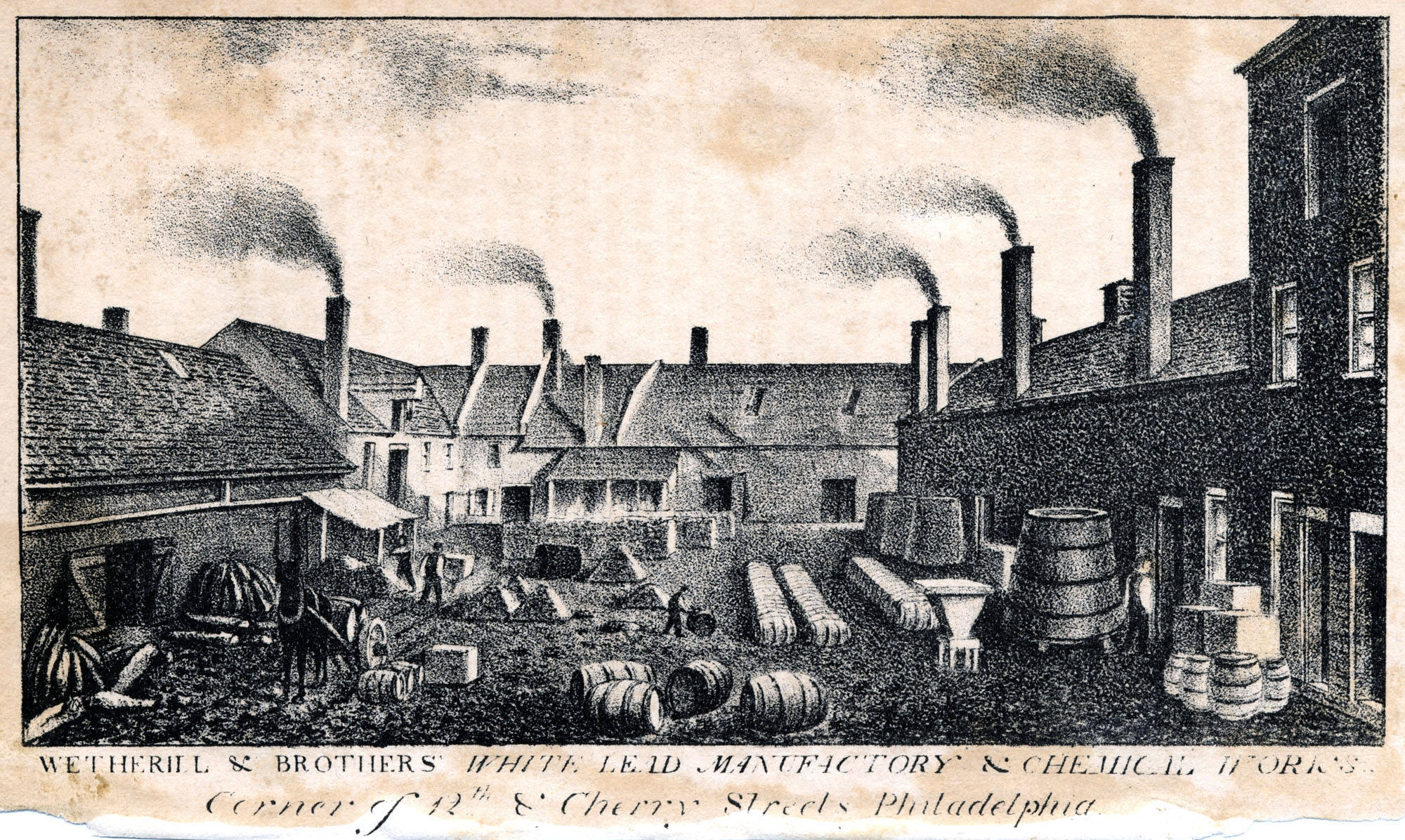

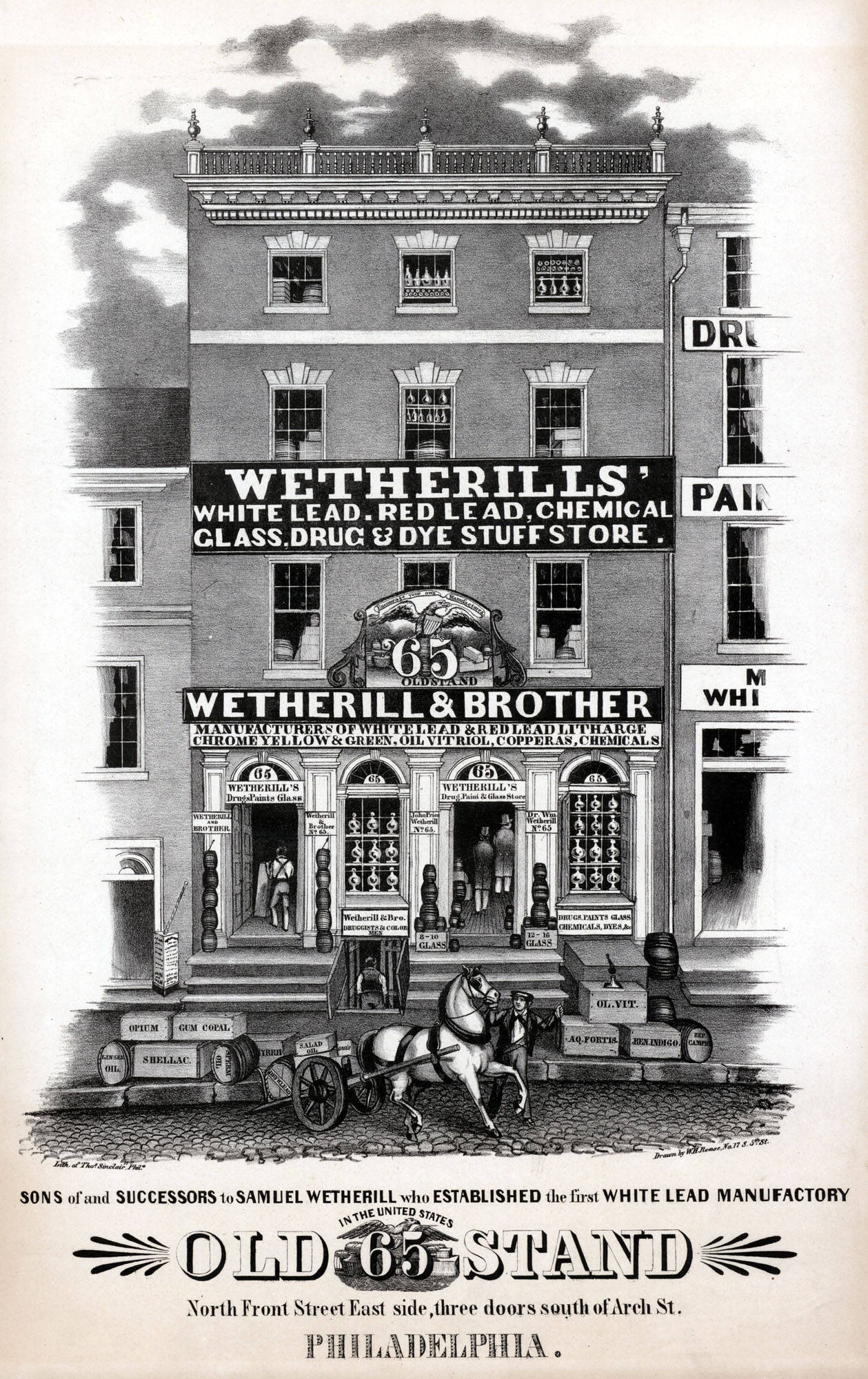

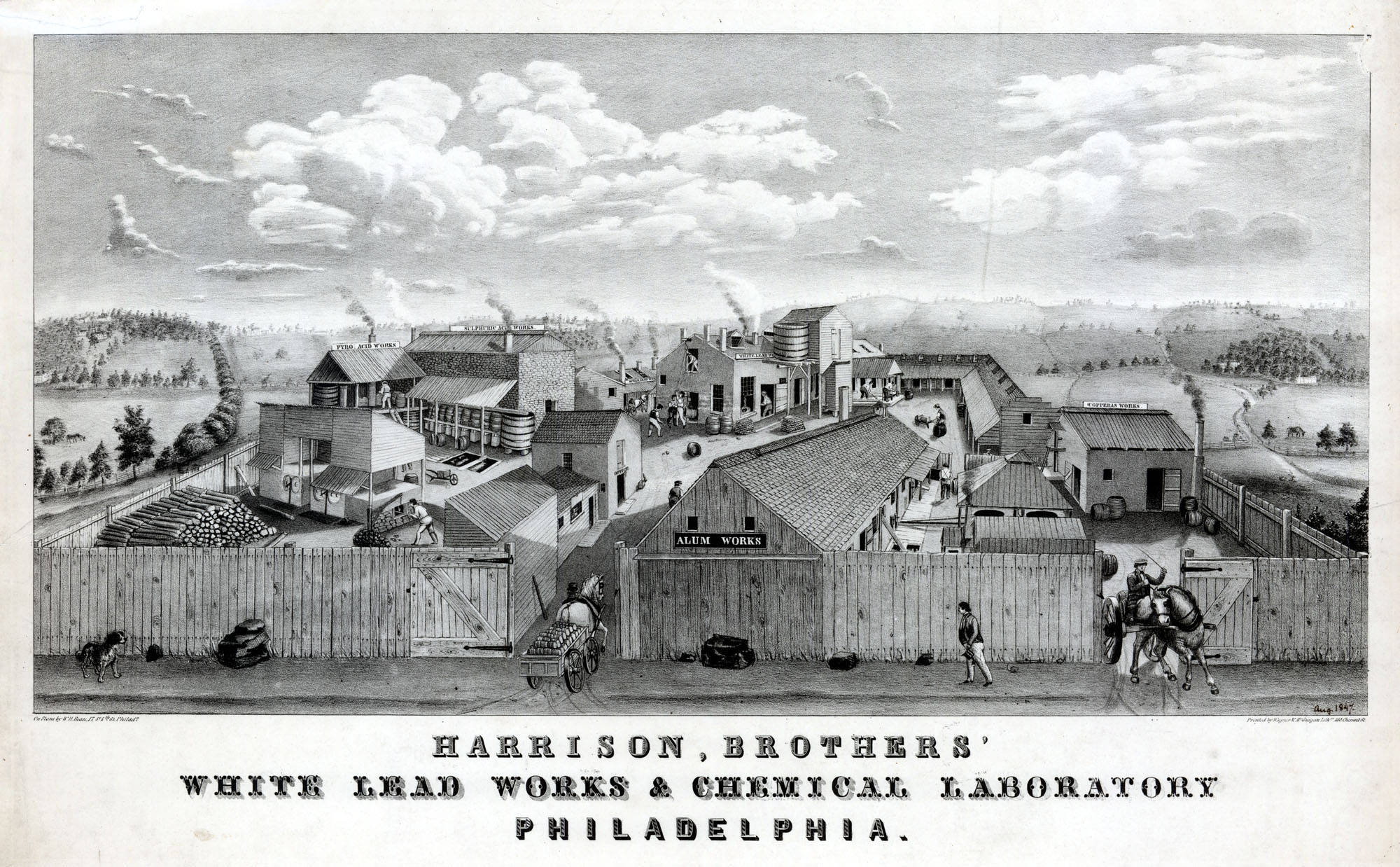

Philadelphians initiated in the U.S. the transition from imports and small-scale preparation to large-scale manufacturing of paint materials. Samuel Wetherill (1736-1816), a former textile manufacturer once in business near Market and Fifth Streets, ventured into drug, dye, and pigment-compounding during the 1760s after the Crown suddenly increased taxes on these commodities. He was an ardent revolutionary and early advocate of domestic manufacturing. His son, Samuel Wetherill Jr. (1764-1829), erected a factory in 1809 at Broad and Chestnut Streets to produce lead pigments. In 1810, his white lead production amounted to 369 short tons. His business prospered, and by 1845 the family company Wetherill & Brothers had a network of sales agents and retail stores in Baltimore, Norfolk, Boston, Providence, Richmond and New Orleans. The company expanded production in 1847 with a new paint factory on South Thirtieth Street, on the bank of the Schuylkill. John Harrison (1773-1833), a trained chemist, druggist, and manufacturer of “oil of vitriol” (sulfuric acid) at Third and Green Streets, also successfully engaged in large scale manufacturing of white lead during the 1810s, when he erected a plant in Kensington. The family company, Harrison Brothers, then opened permanent offices in New York City, and later in Cincinnati after erecting a new factory on Gray’s Ferry Avenue between Thirty-Fifth and Thirty-Sixth Streets in 1863.

By 1870, twenty-nine establishments manufactured paints and varnishes in Philadelphia and Camden counties, including sixteen manufacturers of lead pigments, for a total product value of $ 2.5 million (current 1870 dollars, or $43.8 million 2013 dollars), disproportionately contributing to 11 percent, in value, of the national production of paints and varnishes. But the early lead pigment factories of Philadelphia had by that time lost their monopoly, or even anything resembling domination, over white-lead production in the young Republic, as competitors from Missouri, Ohio, and Illinois achieved much larger scale than the Wetherill and Harrison companies. Following an industrial trajectory taken by other prominent Philadelphia manufacturers, paint manufacturers did not compete head-on against distant mass-producers of white lead, but instead maintained a stronghold on specialty paints and fostered a diversity of products on which they prospered. They continued manufacturing, importing and marketing expensive pigments, varnishes as well as other chemicals, and even spices in the case of Wetherill & Brothers. C. Schrack and Co., 80 N. Fourth Street in Philadelphia and Fifteenth and Mickle Streets in Camden, was famous for its fine varnishes and dry color pigments. Founded in 1816 by Christian Schrack (c. 1790-1854), a former carriage maker, the company supplied specialty paints and varnishes to numerous local and remote coating-consuming companies, including Delaware shipbuilders, the Baldwin Locomotive Company, and the Pennsylvania Iron Works, as well as French carriage makers. Numerous varnish formulas secretly kept by Schrack and Co. have survived, and hint at the diversity of materials, processes and tricks that together constituted the material basis of the trade.

From a consumer point of view, the advent of “ready-mixed” paints, sold in cans ready to stir and apply, was arguably the most important contribution of industrialization to the paint trade during the nineteenth century. The driving force was less economic patriotism, as in the industry’s early development, and more the prospect for paints and varnishes as commodities and consequently, the trade’s potential access to a mass market. Ready-mixed paints transformed the regime of on-site paint preparation and condensed the diverse materials and techniques once required into a single, packaged product controlled by manufacturers. Although Philadelphia did not initiate this revolution—ready-mixed paints were first patented in 1867 by a Cleveland company—its paint companies wasted no time in manufacturing “liquid paint,” as ready-mixed paints were also known. John Lucas & Co., established in 1848 at 33 N. Front Street with a plant in Gibbsboro, Camden County, marketed “Lucas Liquid Paint,” and George D. Wetherill, heir of Wetherill & Brothers, “Atlas Ready-Mixed Paints.” Harrison Brothers became popular for its “Town and Country” brand, first introduced at the 1876 Centennial Exhibition in Fairmount Park. Clearly targeting the house-painting market, the company teamed with Philadelphia-based architects Hazelhurst & Huckel to design appealing advertisements featuring beautiful houses. Revivals of this colorful architectural period, known as “Victorian,” later permeated neighborhoods in West Philadelphia.

Competition and Concentration

Competition and concentration dominated the post-First World War paint industry. Harrison Brothers was acquired by DuPont in 1917. Technical and marketing skills flowed from Harrison to DuPont, and the Gray’s Ferry Avenue plant manufactured some of DuPont’s paint products, particularly zinc-based paints. Later, during the 1950s, DuPont transferred its production capacities to other sites and turned the plant into a research and development center on coatings. The Gray’s Ferry Avenue site shut down in 2009. John Lucas and Co. was acquired by Sherwin-Williams in 1930, and its Gibbsboro plant closed in 1978.

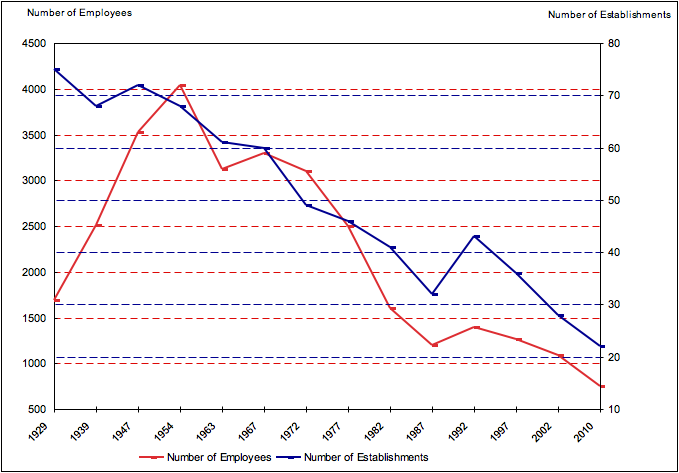

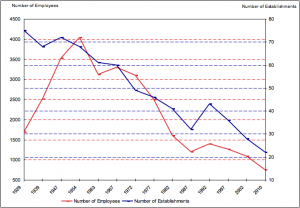

Harrison’s and John Lucas’s company trajectories encapsulated the trends of Philadelphia’s paint industry during the second half of the twentieth century. In a period of citywide and nationwide deindustrialization, Philadelphia’s paint industry declined in absolute terms and as a proportion of the city’s overall industrial capacity. At its peak in 1939, paints and varnishes establishments represented 1.1 percent of all the manufacturing establishments in Philadelphia, but dropped to 0.5 percent by 2010. During the same period, the proportion of the nation’s paints and varnishes enterprises in Philadelphia declined from 5.8 percent to 1.8 percent, while the associated proportion of employees shrank from 6.8 percent to 2.3 percent. By the twenty-first century, few remnants remained of the companies that provided color and protection for homes and industries in the Philadelphia region, the nation, and the world.

Augustin Cerveaux is an independent scholar and former fellow of the Chemical Heritage Foundation.

Copyright 2013, Rutgers University.

Gallery

Backgrounders

Connecting Headlines with History